BÖCKELT TOWER® Exchange Tower

HIGH STORAGE CAPACITY WITH CONCURRENT INCREASE IN MACHINE CAPACITY UTILISATION.

sheet metal panels, sheet metal packages.

By loading the video, you agree to YouTube’s privacy policy.

Learn more

The complete solutions for your sheet metal storage

THE BÖCKELT TOWER® PROVIDES THE HIGHEST FLEXIBILITY IN STORAGE your sheet metal.

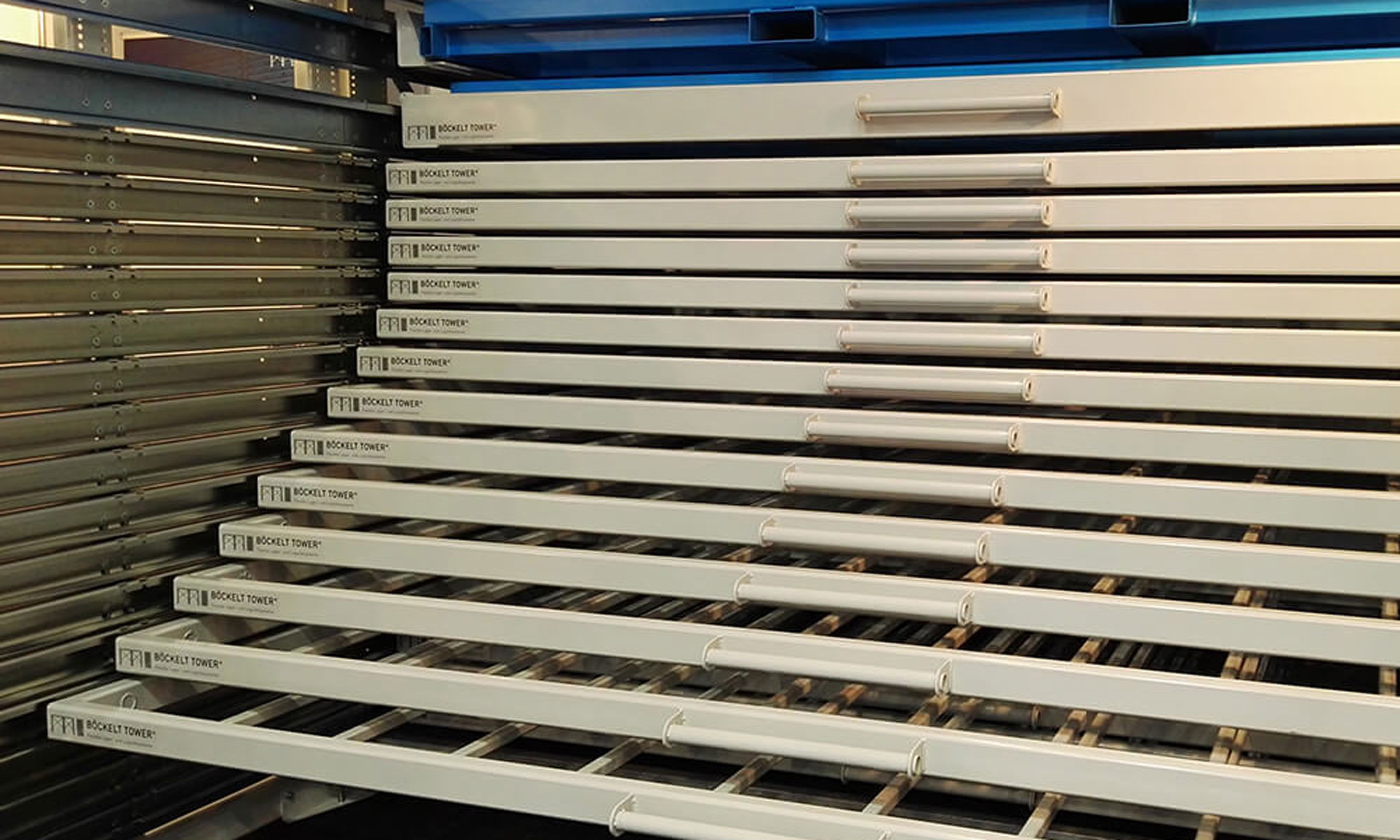

It is used for efficient stocking and provision of metal sheets, metal plates, entire metal sheet packages, as well as pipes, pallets, profiles and other material in the vicinity of the machine. Laser machines, gantry cutting systems, saws, punches, bending machines and other equipment can be loaded, i.e. charged, directly from the exchange tower. The Böckelt cassette storage system can be fitted onto the custom-equipped drawer rack. Without forklift support the BÖCKELT TOWER® exchange Tower offers the possibility of easy material swap in seconds and fast access to a variety of materials.

Profound sheet metal storage solutions

MATERIAL SWAP IN SECONDS, PROCESS OPTIMISATION WITH THE BÖCKELT TOWER® EXCHANGE TOWER.

With a custom-equipped drawer storage system as the basis, fast accesses are achieved at a continuous high level of operational safety and reliability. The rack system’s ease of movement and the ability to combine different drawers ensure maximum efficiency and boost productivity. In addition the drawer rack can be supplemented with the fitted on cassette system to effectively increase storage capacity through utilisation of the room height and to provide additional storage space. The BÖCKELT TOWER® exchange tower can be operated from the front and rear. Likewise, re-storage of produced parts into the exchange Tower is possible, which considerably offloads space demands on surfaces in the area of machines. The rack system is highly flexible and adapts to spatial conditions.

Shelving for metal sheets as a safe and orderly solution

In addition, the drawer rack can be supplemented with the attached cassette storage system to effectively increase the storage capacity by utilizing the room height and to create additional storage space. The BÖCKELT TOWER® changing tower can be operated from the front and from the rear. A return storage of produced parts into the shuttle tower is also possible, thus considerably relieving areas in the vicinity of machines. The rack system offers high flexibility and adapts to the spatial conditions of the sheet metal storage.

Your contact to BÖCKELT TOWER®

Do you have any questions?

Can you provide us with a video or prepared sheets? Then we can help you much better.

Virtual showroom

Exchange tower digital

Click on the button to load the content from showroom.boeckelt-tower.de.

CRANE ATTACHMENT IS POSSIBLE ON ALL FOUR CORNERS OF THE BÖCKELT TOWER® EXCHANGE TOWER.

The doors of the drawer system pivot and are operated via the convenient lifting device. Alignment occurs in the end position, which also ensures ease of movement in loaded status. In the pull-out elements the materials and cassettes are made ideally accessible for cranes and vacuum lifting devices. The BÖCKELT TOWER® exchange tower is built with such stability that an easy-rolling crane with vacuum lifting device can optionally be installed on all four corners. Thus removal of individual sheet metal plates or other materials is fast and easily possible. The advantages of the dynamic storage system with a Böckelt Tower® are obvious: Machine idle times are avoided, movement is spared and access times are minimized.

THE INTELLIGENT SYSTEM WITH INTERCHANGEABLE FRAMES, UNIVERSAL FRAMES AND COMPACT FRAMES.

The flexible drawer system is optionally equipped with different drawers. Interchangeable frames are for direct mounting of system cassettes. An interchangeable frame offers 3 tons of load-bearing capacity and can be inserted in the BÖCKELT TOWER® on both sides. With the universal frame, it is possible to use various sizes of system cassettes. The self-supporting construction enables provision of material, such as metal sheets, on wooden pallets. The compact frame enables direct accommodation of sheet metal plates, metal sheet packages or other material. For example, with the compact frame loading occurs via crane hangers. The compact frame is characterised by minimal space requirements in the system, as well as custom dimensions, load-bearing capacities and load heights. In addition the intelligent BÖCKELT TOWER® software and corresponding transponder system contribute to an extremely smart racking system solution. Learn more about the smart solution from Böckelt.

BÖCKELT TOWER®

Interchangeable frame

- Direct mounting of system cassettes

— Three tons load-bearing capacity

— Can be inserted in the exchange frame on both sides

BÖCKELT TOWER®

Universal frame

Self-supporting construction Use of different-size system cassettes Provision of material on wooden pallets

BÖCKELT TOWER®

Compact frame

Direct mounting of metal sheet packages Loading by means of crane hangers Low space requirements in the system Custom dimensions, load-bearing capacities and loading heights